Adapt and Build Domain Skills to Lead: Delta Thailand R&D Director’s Secrets to Elite Achievement

By David Nakayama - Published November 20, 2022

Interview with CH Lim, Delta Thailand CDBU R&D Director

Text and Photos by David Nakayama, DET Corp Comms

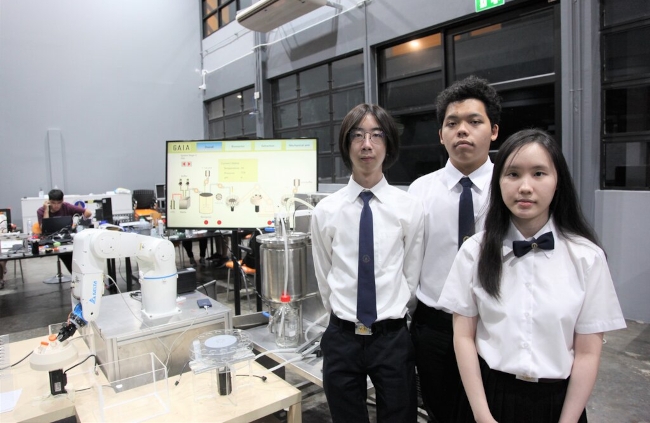

Samutprakarn, Thailand, October 5, 2022- As the largest public-listed electronics company in Thailand, Delta has a world-class power electronics R&D team pushing the boundaries of efficiency. Here, Delta Thailand offers ambitious and skilled Thai engineering talent the chance to do “real R&D” work beyond simple tasks like testing or localizing products.

I sat down with our veteran and genius R&D Director CH Lim at our DET R&D department who talked about his career in Taiwan and Southeast Asia and the evolution of the power supply industry. He also revealed his secrets to raising and managing an elite patent-winning local R&D team in Thailand and living abroad as an intellectual leader at Delta. A key takeaway from his fascinating life story is that choosing the correct career path and having the right domain skills to add value may be the determining factor between either mediocrity or leadership.

Can you please share with us your background?

I’m a Malaysian from Taiping, Perak State. In 1992, I graduated from National Cheng Kung University in Taiwan and began working at a Taiwanese electronic instruments company that produced lab multi-meters, lab power supplies, function generators and oscilloscopes. After one year, I transferred to the factory in Penang, Malaysia. I handled both product qualification and new product introduction for two years gaining a solid electronics background.

In 1994, I read an article introducing a new type of switching power supply that operated at a much higher frequency than existing technology reducing device size to more than half and increasing 20% efficiency from 50%+ to 70%+. At the time, we needed bulky transformers and capacitors for conventional frequencies of 50/60Hz because we didn’t utilize tech like MOSFETs which we’ve had for more than 20 years now.

I decided to move into switching power supplies because I was convinced that this was the future and I joined a Taiwanese company in my hometown making switching power supplies. For over four years, I managed the entire engineering team including product, test, industrial and facility engineers and even the technician who did repairs. Then in 1997, a lot of production began moving to China. I felt there was more value in RD and decided to change my field even though I didn’t have any product development experience.

I got the opportunity to join R&D at Emerson (Formally Nortel power group). I worked to expand R&D for two years before the dot.com crisis. When Nortel stopped operations in Penang, I had two choices:

1. Stay in Malaysia and change my line of work

2. Continue working with switching power supplies as an expat abroad

How did you come to your current role as head of Delta Thailand CDBU Design?

I had several opportunities in Asia and eventually chose to join Delta Thailand in 2001. Our COO then Stronger Wang interviewed me and wanted me to join Production because of my background but I insisted to stay in R&D. I told him I intended to stay in Thailand for at least five years but he advised me to consider a long-term career here. I’ve been here over 20 years already so obviously there is something good here.

Back then DET R&D was a design pool with more than 200 engineers designing for different BUs. I joined as a section head of a design team making Voltage Regulator Modules (VRM) which was a very hot product at the time. The Pentium 3-4 CPUs at the time were faster and consumed more current so manufacturers couldn’t put them directly into the motherboard and had to make a separate module. However, as the technology changed and CPU design had multiple cores the VRM product was discontinued and CPUs were integrated into the motherboard.

In 2008, I began concentrating on our custom design power (CDBU) products. By then our central pool design teams split into teams directly reporting to BUs. Over the years, our products grew and changed according to the market. I also worked with our industrial and medical (IMBU) team in Teningen, Germany. Last year, our DET CDBU head Sherry Xue was promoted to Deputy BG head in Taiwan. Since then, my service area further expanded to cover QE (Quality Engineering), TE (Test Engineering), CE (Component Engineering) and Product Safety.

Congratulations on the international patents you and your team has won. How did DET R&D become such a successful pillar in Delta’s global product development?

Delta Thailand is an MNC with a good organization in terms of product R&D and our Corporate Legal and Patent teams in Taiwan always look for ways to protect our intellectual property (IP) because Delta’s switching power supplies are ahead of the market. Patents protect us by:

Delta Thailand is an MNC with a good organization in terms of product R&D and our Corporate Legal and Patent teams in Taiwan always look for ways to protect our intellectual property (IP) because Delta’s switching power supplies are ahead of the market. Patents protect us by:

- Excluding competitors from using our technology to develop or produce products for import/export.

- Cover intent of selling so competitors cannot promote their products with our patented technology.

Since 2013, I have worked with our Taiwan corporate team to secure patents for technological inventions that can be in multiple products. The corporate team has patent engineer teams and lawyers specialized in patent law. Delta Thailand makes 3-5 patent families per year and we have already created 40-50 patent families with 150 individual patents for DET CDBU, Industrial Power Supplies (IPS), Computing and Networking (CN) BUs and Production.

We have patent guidelines and online tools for application and clear incentives to encourage anyone on the team to participate. Each patent team can get 30,000 baht for their 1st patent and 10,000 baht for 2nd country patent or related patents until they reach the maximum incentive of 90,000 baht. You can even get up to 9,000 baht for just successfully filing a patent application.

What are Delta Thailand’s R&D advantages compared with the R&D of other global electronics companies in this country?

Although many electronics companies in Thailand claim to have R&D in actuality most of this “R&D” work is only new product introduction (NPI) which is taking the product designs from the global HQ and introducing it to local production. Because the role and scope of local R&D are limited, departments don’t have a complete structure with full function.

Although many electronics companies in Thailand claim to have R&D in actuality most of this “R&D” work is only new product introduction (NPI) which is taking the product designs from the global HQ and introducing it to local production. Because the role and scope of local R&D are limited, departments don’t have a complete structure with full function.

In contrast, DET has been a full-function local R&D center since 1995 and we have good connections to our related Delta R&D hubs located in different countries. So we can provide a very good learning environment compared to other electronics companies in Thailand.

We also have global networking opportunities so our young Thai engineers can interact easily with their counterparts in Germany, China and even our global research lab. This provides a lot of practical and up-to-date training in new technologies that are not easy to get at other Thailand companies.

Can you give us a very general idea of the major processes or steps involved in the development of a new product at Delta Thailand R&D?

When I first started in R&D 20 years ago, Product development process typically had five steps:

- Bread boarding: Using some integrated circuits IC and tests to prove our theory

- Prototype: Create a more complete model when we are more confident

- Engineer Verification Test(EVT): Test to ensure the product meets function requirements

- Design Verification Test (DVT): Test to ensure the product meets requirements under all influencing environment factors and Electromagnetic Compatibility (EMC) standards, and certify the product according to required safety standards.

- Pilot stage: Trial run production lines

Today, we can skip steps 1-2 and jump straight to the Engineer Verification Testing because we use simulation technology for the first stages. Before we just followed customer requirements to make a prototype for verification. Now we produce our platform product to introduce to our customers and go directly to EVT without a prototype.

We know enough about our industry and the market to stay ahead and propose the next generation product to our customers. So simulation technology is a very important development and is the future of R&D.

What do you think are the top qualities of an outstanding R&D engineer?

In my hiring process, I look for engineers with a solid understanding of our industry technology from switching power supplies to renewable energy. We want people who are enthusiastic to stay at the forefront because if you stop for even 1-2 years you will fall behind. Elite R&D engineers must always be in an endless learning session that isn’t only limited to working hours.

In my hiring process, I look for engineers with a solid understanding of our industry technology from switching power supplies to renewable energy. We want people who are enthusiastic to stay at the forefront because if you stop for even 1-2 years you will fall behind. Elite R&D engineers must always be in an endless learning session that isn’t only limited to working hours.

Of course, great R&D engineers must also have a good business mind. Remember, the product is not your toy to just play with and then you don't care about producing any benefits. All our work must contribute to the company and we need to have the mindset of adding value to the customer.

You are the leader of an elite engineering team with many patent holders. How do empower and help grow the careers of such a high-powered and intellectually brilliant group of individuals?

There are two ways an R&D engineer can grow their career. The first is as a technical expert in a challenging role in our rapidly changing field. As long as they continue to grow they will increase their domain authority and can even be responsible for a business unit. Design engineers can go on to work more in design simulation and virtual analysis and testing engineers can now move into auto-testing and virtual verification tests.

The second career path is to be an R&D manager which requires excellent product management skills and the ability to manage requirements while efficiently leading a team of 20-30 engineers. We can develop people with this mindset and broad skill set to become section head or department leaders.

How does Delta Thailand R&D continue to stay competitive globally and attract the best electrical engineering talents in the highly competitive Asian region?

As a global R&D team in Thailand, we need to help our engineers adapt their work to real-world applications and business sensibilities. This includes how to save energy and reduce the product's carbon footprint. Besides green energy, we also move towards simulation using our Delta Smart Design with the ultimate goal of producing a digital twin.

As a global R&D team in Thailand, we need to help our engineers adapt their work to real-world applications and business sensibilities. This includes how to save energy and reduce the product's carbon footprint. Besides green energy, we also move towards simulation using our Delta Smart Design with the ultimate goal of producing a digital twin.

Thai universities are just touching on the latest technology but this is not enough for the global market so we set up a team to help new talents learn simulation. However, in the past couple of years, I noticed more and more fresh grads we interview have some skills and understanding of new technology.

What do you enjoy besides work? Do you have any tips for enjoying life while working abroad?

Besides work, your family is one of the critical factors for success. My family moved back to Malaysia so my children receive a multilingual education but we still spend a lot of time together so I won’t miss out on their growth.

Besides work, your family is one of the critical factors for success. My family moved back to Malaysia so my children receive a multilingual education but we still spend a lot of time together so I won’t miss out on their growth.

With budget airlines, it only costs around 3,000 baht to fly home and before COVID I would visit my family every 3-4 weeks. In the past, we had to make international calls but now I can switch on Skype when I get home for face time with my family all evening.

I used to do online homework reviews with my children on the weekends to keep a close connection with them. Now my youngest children will enter university and so our quality of life as a couple will improve. Every year, I organize overseas trips with my family to have some quality time together.

Personally, I don’t feel any inconvenience being apart. In fact, one unexpected experience of myself and other married expat colleagues I know is that we suddenly have free time alone to concentrate on our own projects or research.

Finally, is there anything you would like to share with your Delta colleagues around the world?

The past three years of COVID have changed our way of life and work but I hope everyone will take care of their health and stay safe.

From talking and exchanging ideas with friends, I realize that most people who are positive and react fast can go in the right direction. However, those who hesitate to change by themselves may later find themselves in a less ideal situation where it is very difficult to apply your skills and reach your full potential.

The next-gen has many new challenges we never faced before, like simulation and other new technologies, so change fast and proactively adapt to build the right skill set for your success today and in the future.