RENEWSI: A Thai Startup Driving Sustainability and Turning Solar Cell Waste into Batteries Terminals Worth Over Thousand Baht

By Pannida Kattanasri - Published March 27, 2023

Article by Pannida Kattanasri, DET Corp Comms

Image by Mr. Yutthanakon Kanaphan

In its 7th year, the Delta Angel Fund project is a joint effort between Delta Thailand and the Department of Industrial Promotion that continues to support and develop the startup community by providing them with skills and knowledge to thrive in the commercial market.

Today, we introduce RENEWSI, a team that won the 1st Prize award at the Delta Angel Fund project in 2022. We hear from Mr. Yutthanakorn Khunaphan, RENEWSI Co-founder and CTO, who shares his perspective on creating a new startup in Thailand, the team’s goals and future growth plans.

Can you tell us a bit about the project you are working on and how it works?

Today, in Thailand, there is no process to recycle old solar cells. Instead, they are either dumped in landfills or abandoned onsite. The project I am working on can be summed up in one sentence: We turn waste into something valuable. In this case, we take expired solar panels, which typically have a lifespan of around 30 years, and recycle them.

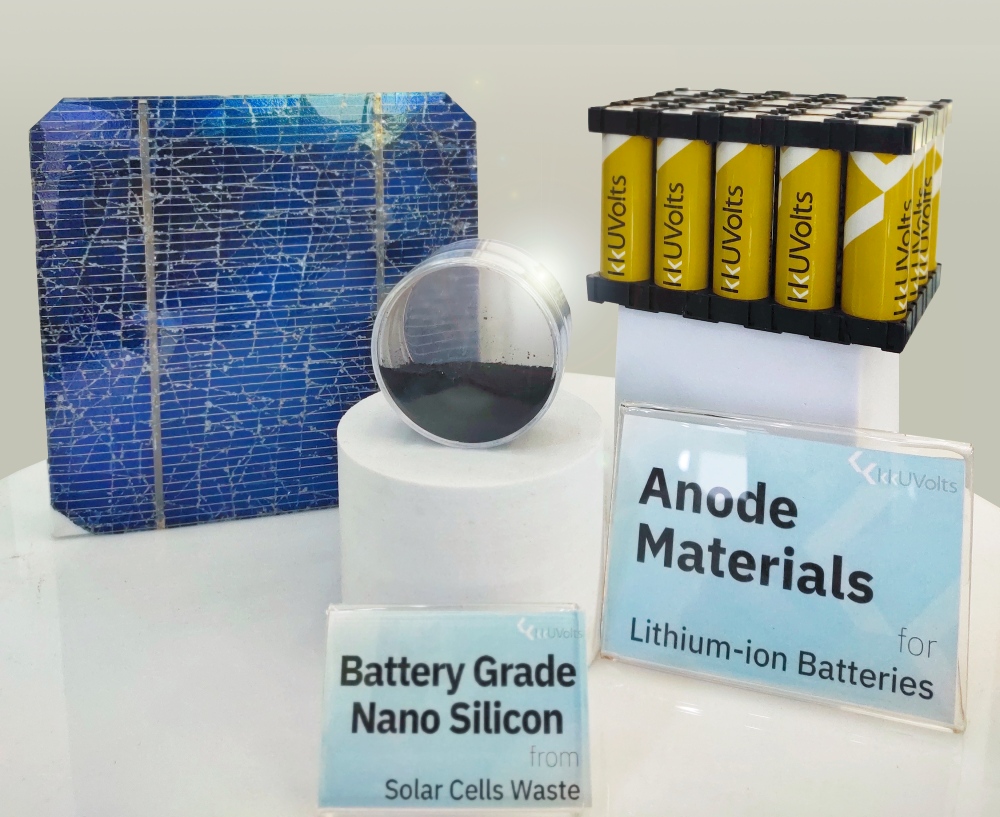

The recycling process involves extracting the blue-colored substance, which is primarily made of silicon, from the panels and turning it into battery electrodes (An essential battery part which is an electrical conductor used to make contact with a non-metallic part of a circuit).

While we are similar to battery manufacturers that recycle waste material for production, our core technology boosts the battery's power capacity and running time as well as its fast-charging capabilities. These are factors that depend on the key materials and technology used in battery production.

What type of batteries are used for what applications?

Actually, we make Lithium-ion Batteries, which can be used to power everything. If you open up your phone you will see that the battery electrodes are all the same material. So, we make electrodes from waste for regular batteries.

Think back to when we used large battery packs, like those found under the hood of the car. Those are lead-acid batteries, which are lower capacity, cheaper and heavier. But why do we have lightweight batteries, like those used in laptops and EVs? These devices require a lightweight but high-density battery, exactly like the Lithium-ion battery.

As Lithium-ion batteries replace other types of batteries in the market, we need more positive and negative electrodes. Solar cells can be used to make negative electrodes. One solar panel weighs about 20kg and contains about 1kg of silicon. Normally, the value gained from of a single recycled solar panel is only about 50 baht, but we can increase this value by making a high-grade silicon battery worth around 1,000 baht.

Who are the members of the RENEWSI team and how did they come together?

The main members of the RENEWSI team are myself and my university professor who taught me from undergraduate to doctoral level. We have been making batteries since the beginning, and my professor is the co-founder of RENEWSI, who already had her own battery factory.

Our support team has another retired teacher who trained pilots in America. He helped me in terms of engineering knowledge and language skills to present my work. For marketing, the Vice President of the Thai Chamber of Commerce Association, helped us to change our perspective in presentation and understanding the real business opportunities. We also have an R&D team of 30 people at our factory team to bring the RENEWSI team to a total about 50 people.

Where did the name RENEWSI originate from?

When we were choosing our team’s name, we thought of something that links up with recycling. But actually, the word "SI" comes from the word sand or “sai” in Thai, which solar cells are made from. Or we can say it means Renew + Si (Silicon) because this element is in our product. Recently, some people called us RENEWSIZE, because our product can control the size of silicon. So it’s a name that’s open to interpretation which I like a lot :)

How significant is the problem of solar panel and renewable energy waste in Thailand, and why did you decide to undertake this project?

We are seeing an exponential increase in solar panel installations all over the world. Yet as demand for solar panel installation increases, we have the issue of waste management because these solar cells have a limited lifespan. Moreover, the current situation in Thailand is almost 100% waste to landfill. But we do not want this to go on as it’s not a circular economy model and is not sustainable.

According to statistics in 2022, the Department of Industrial Works alone has registered approximately 4,000 tons of solar cells that have reached the end of their lifespan. This is excluding solar cells in household units and other sites. It is estimated that in around 12 years, this waste will become millions of tons.

So I feel that I have to do this project because Thailand doesn't have a solar panel recycling industry yet. We are the first company in the country to successfully convert metal grade silicon to battery grade silicon. In fact, there is no company in the world today that has successfully created batteries from solar cells. We may be the first in the world to achieve this.

Where do you think RENEWSI’s position is in Thailand's green industry, and in what direction do you think you will grow?

We are only in our startup phase now. The next thing we need to be do is to focus on our manufacturing plant to have a production line that can expand capacity to many kilotons in the future. This is possible because there are a lot of suppliers waiting to dispose waste solar cells.

Nowadays, large battery manufacturers in Thailand import 100% of their chemicals and materials including positive and negative electrodes, or internal components from foreign countries. Typically, anodes (positive electrodes) are made of lithium ore but in Thailand, we don't have any lithium mining. Even graphite for negative electrodes (material used in pencil lead) has to be imported.

I had to prove to that our product is better and cheaper because our process is better for the environment and is suitable for fast charge batteries. When used in an EV, it can run longer because it has more power capacity and it’s safer than other materials used in the market. As the demand for EVs gets higher, the quantity of batteries used will increase as well as demand for materials used to make batteries.

How did you find out about the Delta Angel Fund project, and how does it help you develop your solutions and business?

I got to know about this project because a professor recommended it to me. Initially, I only intended to participate in the project to receive business training, as I had a research background but no knowledge of business. However, after joining I found it helped me to gain knowledge and skills in presenting my ideas better and other practical business aspects. Delta and the Department of Industrial Promotion provided a wealth of knowledge in a short time, emphasizing quality.

At first, I thought I might not qualify for a prize, but when I had the opportunity I gave it my all and make the most of it. Participating in this project helped me learn a lot and highlight my work to a wide audience. It became more involved in teamwork and now think more holistically, making me a better entrepreneur.

Apart from the silicon-grade battery being developed with the Delta Angel Fund project, are there any other projects that you are involved in?

Not at the moment. Right now, we need to quickly bring the silicon to the battery market, which requires a tremendous amount of research, analysis, team building, and factory construction. Since I am a student, the intellectual property belongs to the university (Khon Kaen University), and we need to plan for more exclusive license patents.

The most important thing to do now is to ensure that the quality of the battery grade silicon is better than global market imports. Therefore, we are mainly dedicated to developing this area.

What is your opinion on the small size of the startup scene in Thailand compared to other countries, and what challenges do Thai startups like RENEWSI face?

Of course, the startup scene in Thailand is much smaller than in other countries, and promotion is insufficient. That’s why the Delta Angle Fund project, which is a collaboration between the Department of Industry Promotion and the private company Delta, is very important because it involves creating a community of startups with “Deep Tech” and a platform to showcase their potential. However, it is the responsibility of all sectors to build the momentum for mass support for innovative tech to enable our country to move forward.

Our current challenge is that we are the first to produce batteries from solar cells. We are a brand-new company so why should customers buy our products, especially those our high value products? How can we gain customer’s trust? So branding is our biggest challenge. As an unknown brand entering a niche market, we need to establish credibility. RENEWSI will not stop developing. We aim to create a strong brand both in Thailand and abroad.

What suggestions do you have for entrepreneurs participating in the Delta Angel Fund project for how to transform their initial ideas into profitable businesses?

I suggest startups know their field well and how their specific issues must be solved. When we are deeply involved, it will show to investors both through our attitude and words. We must be sincere in our pitching.

How do you think innovations from the Delta Angel Fund will help create a better future for Thailand?

First, innovation has to be sustainable regardless of if it involves the supplier or the natural resources. We must be mindful of the environment, manage resources, plan well and think things through when forming a business.

Secondly, when we come together to create innovation and form a strong network it will create a ripple effect and many other agencies will start to see the importance of our work. It definitely helps to create a large group of tech start-ups and of course it would be good for Thailand’s economy overall.